Navigating the Waves of Supply Chain Turbulence

In today’s interconnected global economy, supply chains are the lifeblood of businesses. From sourcing raw materials to delivering finished products to customers, a well-oiled supply chain is essential for success. However, recent events such as the COVID-19 pandemic, natural disasters, and geopolitical tensions have exposed the vulnerabilities of supply chains and the need for businesses to navigate the waves of supply chain turbulence.

The COVID-19 pandemic, in particular, has had a profound impact on supply chains worldwide. Lockdowns, travel restrictions, and sudden shifts in consumer demand have disrupted supply chains, causing shortages of essential goods and delaying deliveries. Companies that relied heavily on a single source of supply or outsourced their manufacturing to a single country found themselves struggling to meet customer demand when borders closed and factories shut down.

To stay afloat during times of supply chain turbulence, businesses must adopt a proactive and agile approach to supply chain management. This includes diversifying suppliers, building redundancies into the supply chain, and investing in technology to improve visibility and responsiveness. By anticipating potential disruptions and having contingency plans in place, businesses can better navigate the waves of supply chain turbulence and ensure continuity of operations.

One key lesson from recent supply chain disruptions is the importance of building resilience into the supply chain. Resilience is the ability to adapt to changing circumstances and bounce back from setbacks. Businesses that have resilient supply chains are better equipped to withstand shocks and recover quickly when disruptions occur. This may involve building relationships with multiple suppliers, investing in inventory management systems, and developing alternative transportation routes.

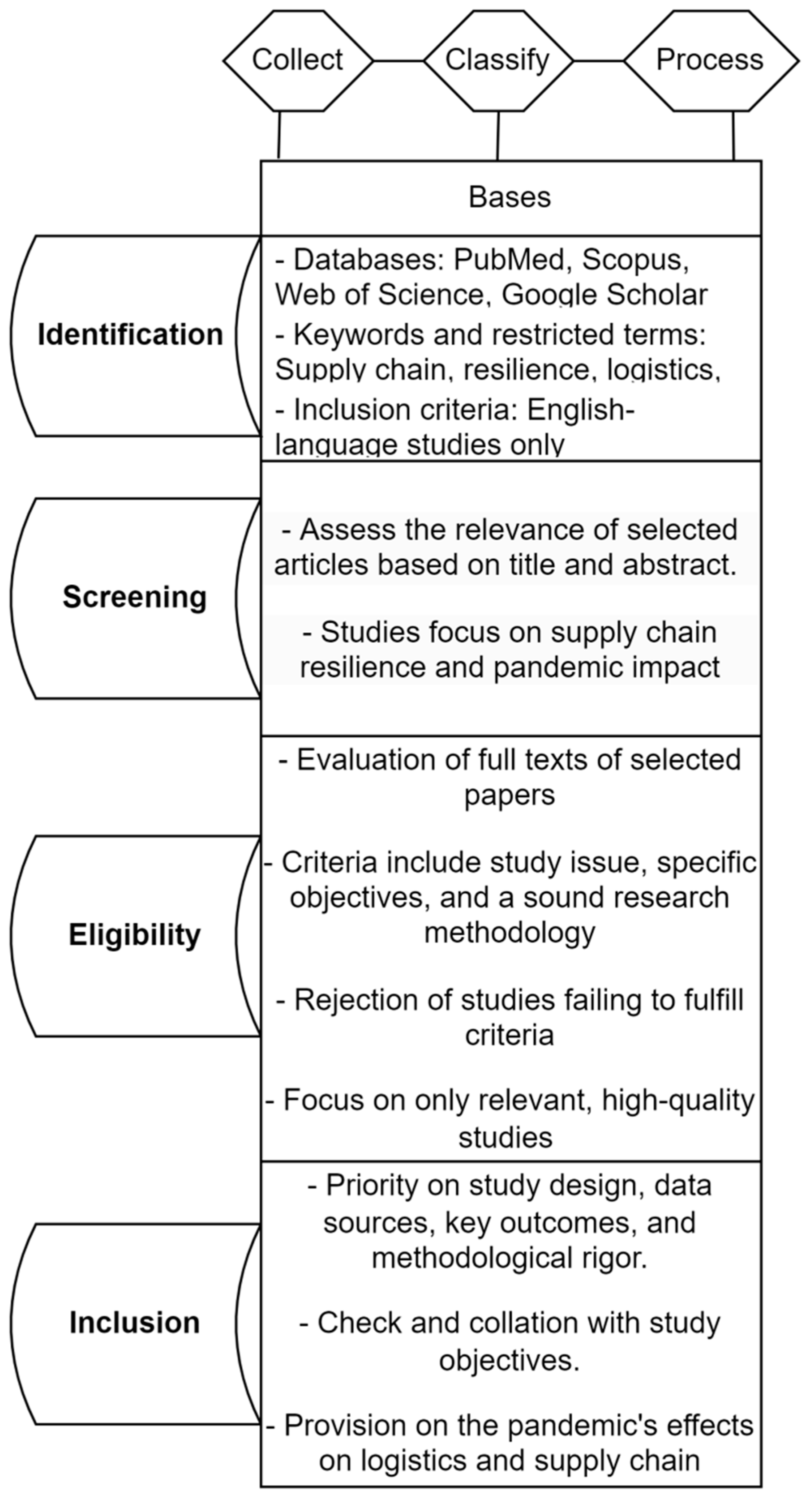

Image Source: mdpi.com

Another lesson from recent supply chain disruptions is the need for collaboration and communication across the supply chain. In times of crisis, businesses must work closely with suppliers, logistics partners, and customers to ensure the smooth flow of goods and information. Transparent communication, sharing of data, and collaboration on risk management strategies can help businesses weather the storm and emerge stronger on the other side.

Innovative technologies such as blockchain, artificial intelligence, and Internet of Things (IoT) are also playing a crucial role in helping businesses navigate the waves of supply chain turbulence. These technologies provide real-time visibility into supply chain operations, automate processes, and enable predictive analytics to identify potential risks before they escalate. By harnessing the power of technology, businesses can improve efficiency, reduce costs, and enhance resilience in their supply chains.

Ultimately, staying afloat during supply chain disruptions requires a combination of strategic planning, operational excellence, and a willingness to adapt to changing circumstances. By learning from recent disruptions and embracing a proactive and agile approach to supply chain management, businesses can navigate the waves of supply chain turbulence and emerge stronger and more resilient in the face of future challenges.

Charting a Course for Resilience and Success

In today’s fast-paced and interconnected world, businesses are constantly faced with supply chain disruptions that can throw a wrench in their operations. From natural disasters to political unrest to global pandemics, there are a myriad of factors that can impact the flow of goods and services from suppliers to customers. However, rather than being caught off guard by these disruptions, businesses can take proactive steps to build resilience and ensure their continued success.

One of the key strategies for navigating supply chain disruptions is to chart a course for resilience. This means having a plan in place to quickly adapt to unforeseen circumstances and minimize the impact on operations. By identifying potential risks and developing contingency plans, businesses can better prepare for disruptions and ensure that they are able to continue serving their customers.

One way to build resilience in the face of supply chain disruptions is to diversify sourcing and production locations. By spreading out suppliers and manufacturing facilities across different regions, businesses can reduce the risk of being completely shut down by a single event. This strategy proved invaluable during the COVID-19 pandemic, when companies that had diversified their supply chains were able to quickly pivot to alternative sources when traditional suppliers were unable to meet demand.

Another important aspect of building resilience is to foster strong relationships with suppliers and partners. By maintaining open lines of communication and working collaboratively with key stakeholders, businesses can more effectively navigate disruptions and find solutions to keep operations running smoothly. Building trust and transparency in these relationships can also help businesses quickly respond to challenges and make decisions that benefit all parties involved.

In addition to building resilience, businesses can also take steps to ensure their long-term success in the face of supply chain disruptions. This includes investing in technology and data analytics to improve visibility and transparency in the supply chain. By leveraging tools such as inventory management systems and predictive analytics, businesses can better anticipate disruptions and make informed decisions to mitigate their impact.

Furthermore, businesses can also focus on building a culture of innovation and continuous improvement within their organizations. By encouraging creativity and flexibility among employees, businesses can more effectively adapt to changing circumstances and find new ways to overcome challenges. This adaptability is essential for long-term success in today’s volatile and unpredictable business environment.

Ultimately, by charting a course for resilience and success in the face of supply chain disruptions, businesses can not only survive unexpected challenges, but also thrive in the long run. By proactively identifying risks, building strong relationships with suppliers, investing in technology, and fostering a culture of innovation, businesses can navigate turbulent waters with confidence and emerge stronger on the other side. So, no matter what disruptions may come their way, businesses that are prepared and adaptable will be able to stay afloat and continue on the path to success.

Navigating Supply Chain Disruptions: Lessons from Recent Events